News

Soonseal

www.sealingwell.com

https://sealingwell.usa72.wondercdn.com/uploads/image/64995865c58b2.png

www.sealingwell.com

https://sealingwell.usa72.wondercdn.com/uploads/image/64995865c58b2.png

The working principle of film packaging machine

Views: 813

Author: Soonseal

Publish Time: 2022-01-14

Origin: www.sealingwell.com

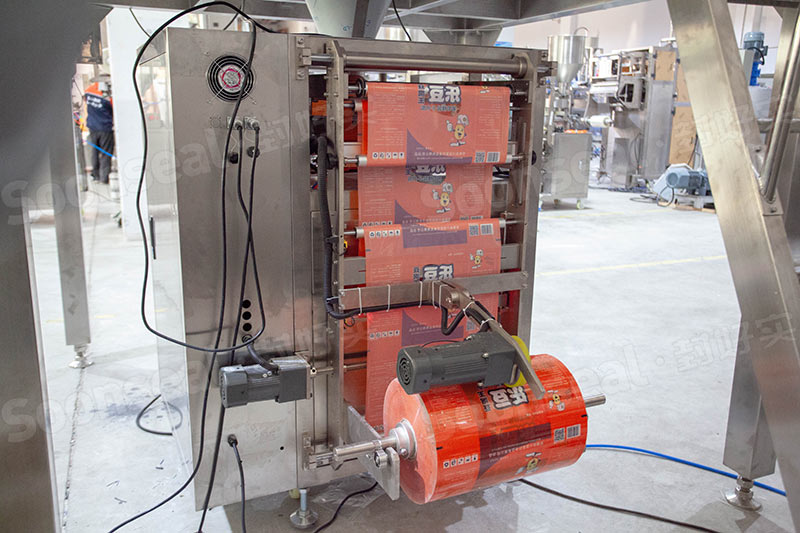

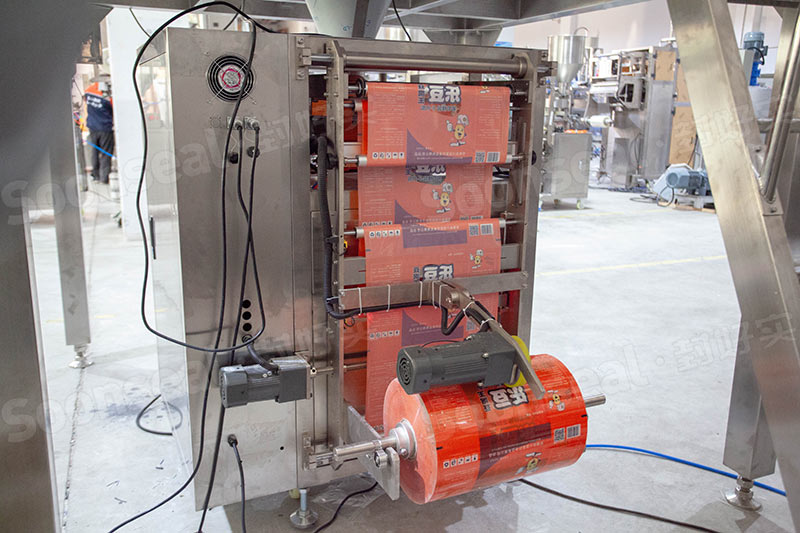

Guangdong Soonseal vertical roll film packaging machine is an ideal bag packaging equipment that meets the requirements of high-quality packaging, small bag type, fast packaging speed, and can realize back sealing, three-side sealing, four-side sealing bag type; suitable for powder, granule, liquid item.

The packaging requirements of various materials such as solid objects and solid objects adopt the packaging method of roll film-forming to improve production efficiency and save production costs.

Technical characteristics of film roll packaging machine:

1. Host frequency conversion speed regulation system: AC motor and frequency conversion speed regulation, stable and reliable operation, low-speed and high-torque, even in the case of large load changes, the same excellent operation.

2. Servo system: The servo motor directly controls the number of revolutions of the blanking screw through the number of pulses. The performance is stable and reliable and the adjustment is simple and quick.

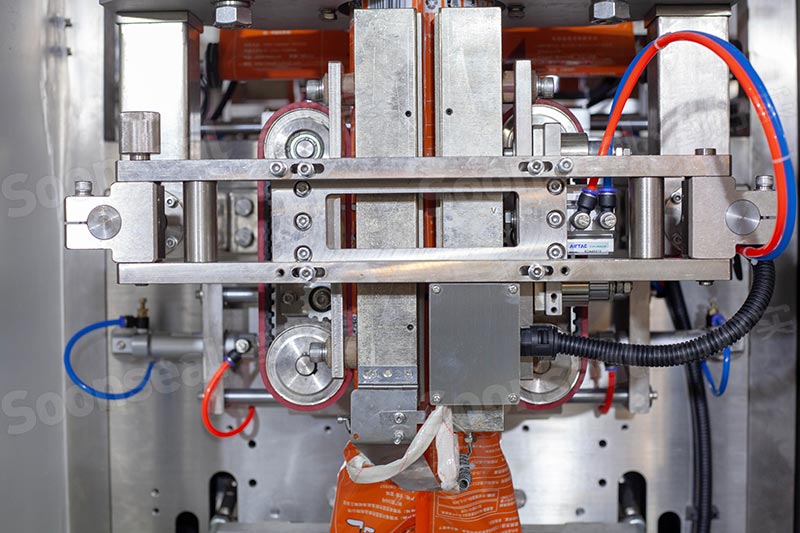

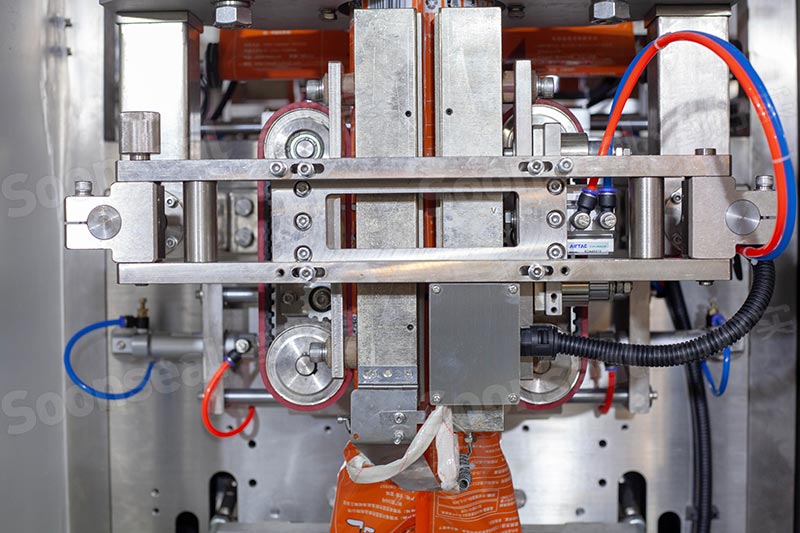

3. Bag-making system: The machine-made bag, sealing and filling are relatively independent systems. The two systems are coordinated and linked through mechanical linkage and programmable logic controller PLC. Therefore, it can be adapted to different packaging objects and packaging bag dimensions.

4. Finished product packaging system: Fully automated production equipment that uses heat-sealable packaging materials (polyethylene film, multilayer composite film, etc.) to automatically complete packaging processes such as bag making, metering, filling, and sealing.

5. Integrated control system: It is composed of PLC programmable computer program controller, frequency conversion speed regulator, etc., with high integration and strong control ability. The application of touch screen technology makes the operation of the machine more reliable and convenient. Photoelectric sensors, encoders, proximity switches, etc. are all advanced imported sensing elements, which make the machine more stable and durable.

6. Servo bag pulling device: using the Panasonic PLC positioning module, positioning can be achieved. The characteristics of stable bag-drawing speed and large torque ensure that the finished bag has a small error and good sealing.

Roll film packaging machine operation process:

1. Bag making: bag making with roll film through bag making machine, which can make back seal, three-side seal and four-side seal bag. Customers can customize logo brand print on film roll to work.

2. Print the production date: the ribbon detection will automatically code on the roll film, the ribbon will stop and alarm when the ribbon is used up, and the touch screen will display to ensure that the packaging bag is coded normally; the steel printing coding method can be selected.

3. Filling materials: testing, materials are not filled, heat-sealed and unsealed to ensure that the bag is not wasted;

4. Heat sealing: alarm for the abnormal temperature to ensure the sealing quality

5. Cooling, shaping and discharging: to ensure beautiful sealing.

Roll film packaging machine is mainly used for packaging granular medicines, sugar, coffee, fruit, tea, MSG, salt, seeds, desiccant and other fine particles. It is suitable for small bag packaging of medicine, food, chemical industry, pesticide, etc.

At the same time, different metering methods can be selected to realize the packaging of liquids, powders and other products.

Soonseal has a professional designer team which can be based on different customers' requirements to design suitable plans, contact us now for more.