Whether you're in the pharmaceutical, foodstuff, cosmetic, or chemical industry, this versatile filler is designed to meet your needs.

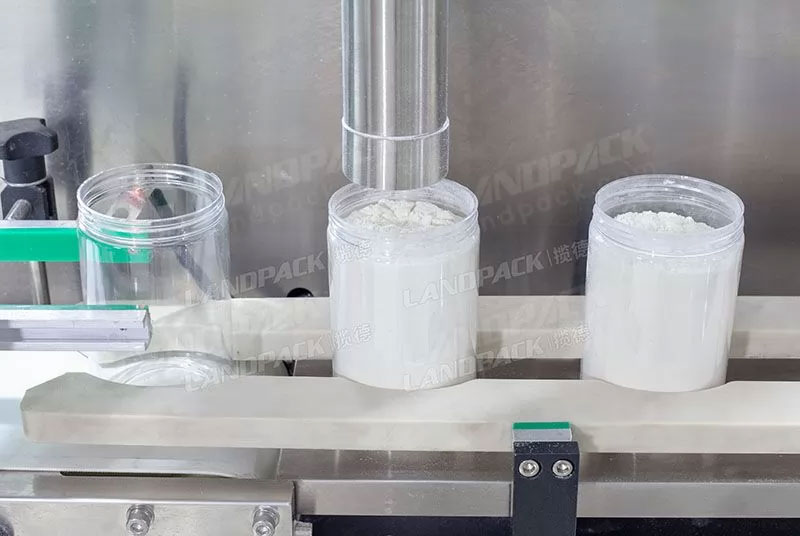

With its advanced technology, the Landpack Automatic Powder Filler excels at accurately filling a wide range of powders, including milk powder, coffee powder, and granular additives. Its precision ensures that each package is filled with consistency and accuracy, eliminating waste and ensuring customer satisfaction.

Designed with productivity in mind, this state-of-the-art filler offers seamless integration into your production line. Its automated features streamline the filling process, reducing labor costs and increasing overall efficiency. You can rely on the Landpack Automatic Powder Filler to deliver reliable and high-quality results every time.

| Packaging Material: |

|

|

|

|

|

|

| Flour |

Flour |

Flour |

Flour |

Flour |

Flour |

| Bag Style: |

|

Seamless integration: The automatic two-head Auger type metering/filling system seamlessly works with the automatic capping machine, allowing for a smooth and efficient production process.

Precision positioning: Equipped with double star wheels and a precision splitter, this filling system ensures accurate positioning of bottles/cans, minimizing errors and ensuring consistent filling results.

High accuracy and stability: The transmission system of the filling machine is driven by a Japan Panasonic servo motor, guaranteeing high accuracy and stability in the filling process, resulting in precise and reliable product weights.

Intelligent automation: This filling system features an auto bottle/can position, lifting, and vibrating mechanism, which automatically stops filling when there are no bottles present or if a bottle jam occurs, enhancing operational safety and efficiency.

Versatile memory modules: With 10 sets of memory modules, the system can easily store and recall different product parameters and filling weights, allowing for quick and convenient setup for various products.

User-friendly interface: The HMI touch screen provides intuitive and user-friendly control for easy operation and monitoring of the filling process.

Reliable performance: The system incorporates a Japan Panasonic PLC, known for its reliability and durability, ensuring consistent and dependable performance over time.

Flexible connectivity: This filling system offers the option to connect with material supply systems in the pre-section for seamless material flow, as well as the ability to link with capping and labeling systems in the post section, providing a comprehensive packaging solution.