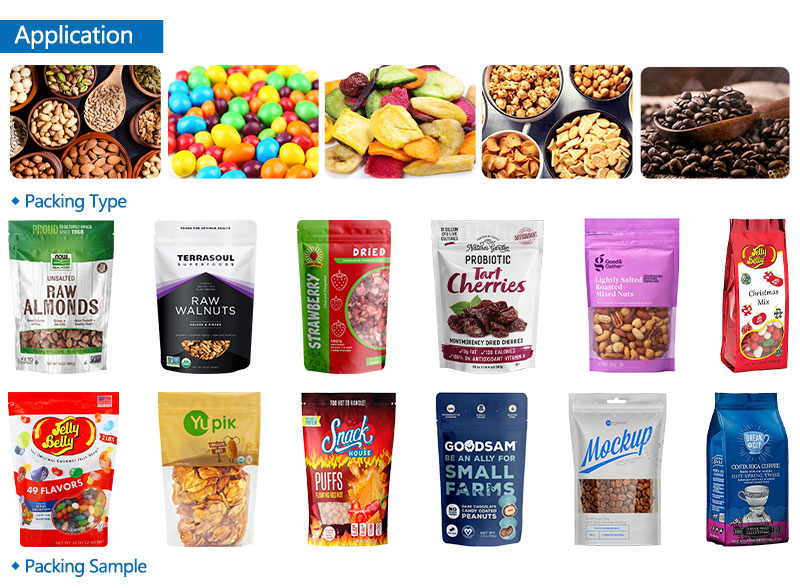

Suitable to use in packing high accuracy and easily fragile material. Such as dried fruit, apple slices, nuts, pet food, puffy food, chips, jelly, candy, pistachio nuts, frozen dumplings, coffee beans, pasta, cotton candy, french fries, rice, small hardware, etc.

Suitable Pouch: Doypack, Box Pouch, Zipper Pouch, Stand Up Pouch, Stand Up Pouch With Hole, Kraft Paper Bag, Side Gusset Bag etc.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

|

Packaging Material & Bag Style:

|

|

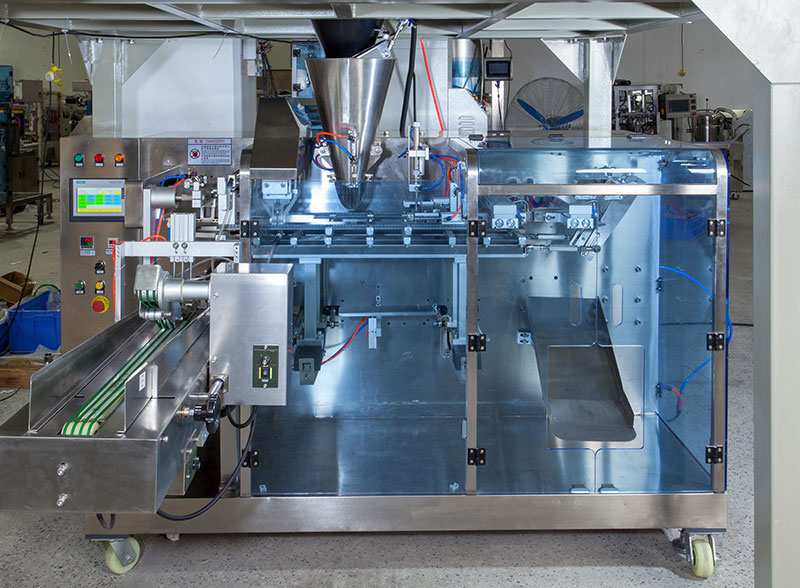

1. Automatic Feeding: The machine automatically loads products, adjusting its speed.

2. Precision Weighing: The multi-head weigher ensures accurate measurement.

3. Quality Components: The machine uses top-quality electric parts.

4. Customizable Station: It adapts to flat-bottom and doypack bags.

5. Double Sealing: Enhances bag appearance and freshness.

Workflow:

1. Z type elevator

2.10 Head High Precision Weigher with Teflon Coating

3. Horizontal feeding bag conveyor

4. Ribbon coding

5. Opening zipper and bag fully

6. Automatic filling→Nitrogen

7. Sealing-Output