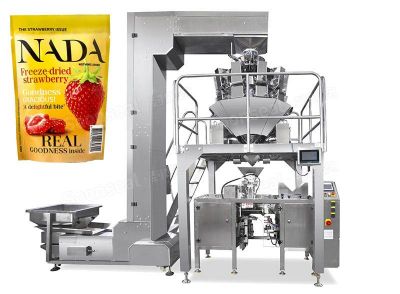

In recent years, dry fruit packaging machines have gradually occupied a dominant position in the packaging market. The many advantages of bags, such as excellent printing appearance, portable opening method (easy to tear), and user-friendly sealing method, keep food fresh, making it the first choice of consumers. Landpack packing machine provides dry fruit manufacturers with more packaging options, material handling strategies, and fully automated solutions.

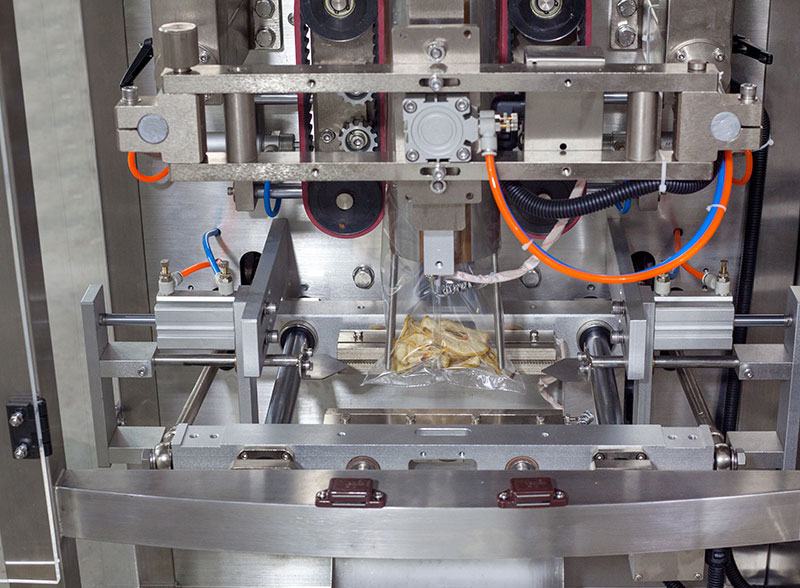

Multifunction dry fruit form fill and seal machine can auto finish material feeding, weighing, filling and sealing, etc.

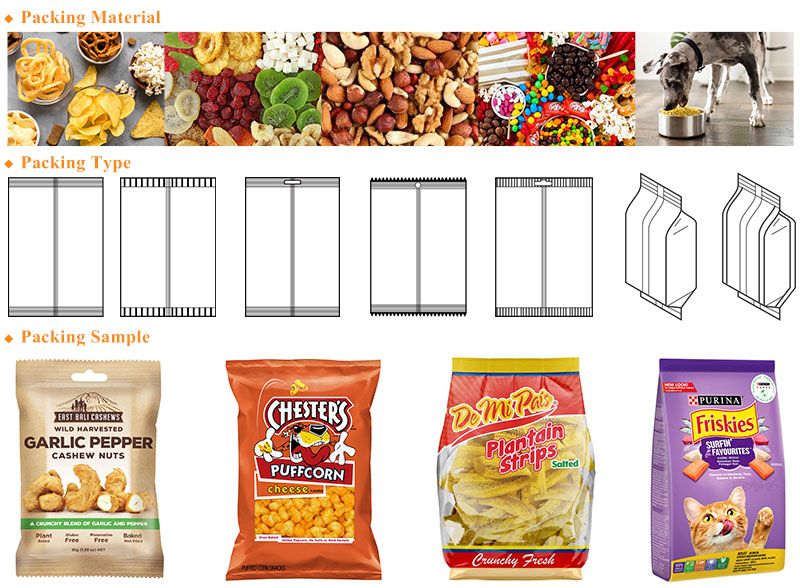

Multifunction Dried Fruit Doypack Fill And Seal Machine is suitable for packing all kinds of grain material, sheet material, strip material, and abnormity material such as dry fruit, beef jerky, nut, cashew, candy, sunflower seeds, peanut, pet food, potato chips, popcorn, almond, vegetable salad, instant oatmeal, etc.

|

Packaging Material:

|

|

|

|

|

|

|

|

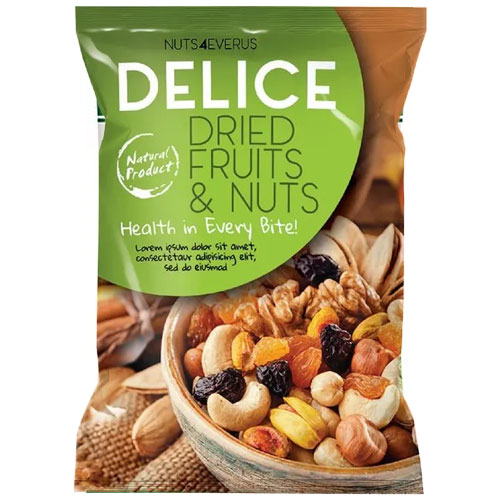

Dried Fruit

|

Dried Fruit

|

Dried Fruit

|

Dried Fruit

|

Dried Fruit

|

Dried Fruit

|

|

Bag Style:

|

|

|

|

|

|

|

|

Back Sealing Bag

|

Back Sealing Bag

|

Back Sealing Bag

|

Back Sealing Bag

|

Back Sealing Bag

|

Back Sealing Bag

|