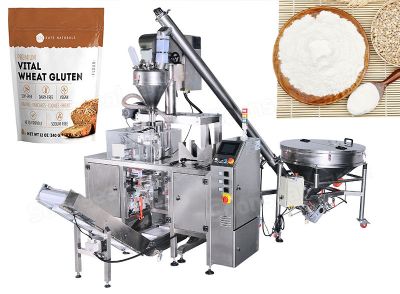

Introducing our automatic flour powder pre-made pouch doypack filling machine, designed to revolutionize the packaging process for a wide range of powdered products. This innovative machine is perfect for efficiently packing various powders such as milk powder, coffee powder, food additives, condiments, tapioca powder, coconut powder, pesticide powder, fertilizer granules, and more.

Equipped with advanced technology, our filling machine is capable of handling different types of heat-sealable preformed side seal bags, fin seal bags, gusseted bags, block bottom bags, zip-lock recloseable bags, stand-up pouches with or without spouts, and other heat sealable pouch variations.

Designed for seamless automation, this machine streamlines the packaging process, saving time and labor costs. Its precision filling mechanism ensures accurate and consistent measurements, preventing product waste or variations in dosage. With its user-friendly interface, operators can easily set up and adjust parameters to meet specific packaging requirements.

| Packaging Material: |

|

|

|

|

|

|

| Flour |

Flour |

Flour |

Flour |

Flour |

Flour |

| Bag Style: |

|

High-Speed and Consistent Production: Our full automatic intermittent rotary machine combined with an auger powder filler ensures efficient and consistent production, allowing you to meet high-volume demands effortlessly.

Durable and Reliable: We prioritize the durability of our machine by selecting heavy-duty components and parts, guaranteeing long-lasting performance and minimizing downtime.

Hygienic Design and Easy Cleaning: Our machine is constructed with hygiene in mind, making it easy to clean and maintain. This feature ensures product safety and reduces the risk of contamination.

User-Friendly Touchscreen Control System: With its operator-friendly design and touchscreen control system, our machine offers ease of use and seamless operation. The advanced PLC and touchscreen interface enhance the man-machine interaction for intuitive control.

Optional Dust Control and Extractor System: Upon special request, we can provide a dust control and extractor system, effectively managing any potential powder dispersion and ensuring a cleaner working environment.

Automatic Bag Checking System: Our machine incorporates an automatic checking system that verifies the bag's position, filling accuracy, and sealing quality. This feature guarantees precise and reliable packaging results.