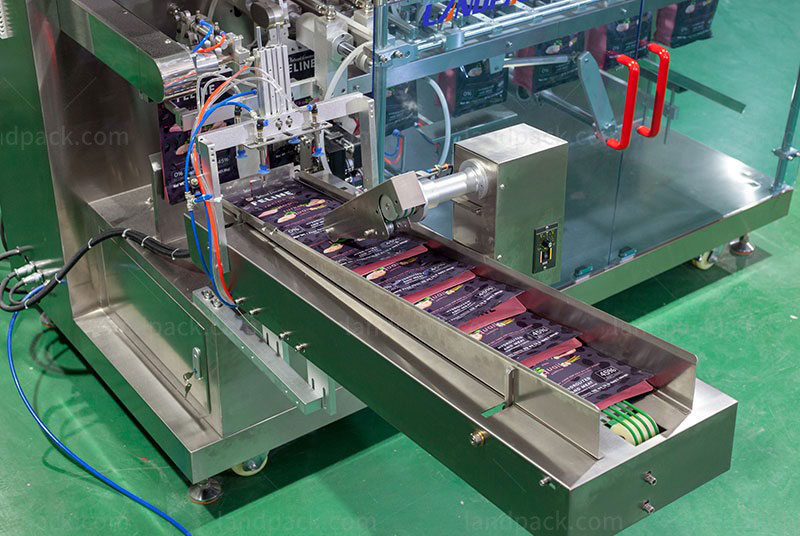

Introducing the LDGP-260D Automatic Flour Powder Horizontal Premade Pouch Doypack Packing Machine, a cutting-edge solution designed for efficient and precise powder filling and sealing operations. This advanced machine boasts remarkable speed, exceptional accuracy, and unwavering performance, making it an ideal choice for various industries.

With its versatile capabilities, the LDGP-260D is perfectly suited for packaging a wide range of powders such as coffee powder, talcum powder, milk powder, spice powder, detergent powder, flour, protein powder, and more. Its horizontal premade pouch design ensures seamless integration into existing production lines, streamlining the packaging process with maximum efficiency.

Equipped with state-of-the-art technology, this packing machine guarantees high-speed operation without compromising accuracy. The LDGP-260D is meticulously engineered to deliver consistent and reliable performance, eliminating downtime and maximizing productivity.

| Packaging Material: |

|

|

|

|

|

|

| Flour |

Flour |

Flour |

Flour |

Flour |

Flour |

| Bag Style: |

|

Versatile and Fully-Automatic: Our packing machine is equipped with multi-function capabilities, allowing seamless integration with various filling systems. This versatility ensures that it meets the diverse packaging needs of different industries.

Labor Cost Savings: With a high-capacity auger feeding machine, our packing machine significantly reduces labor costs. The automated process eliminates the need for manual powder filling, improving efficiency and productivity.

High-Speed and Precise: Powered by a servo motor, our machine offers precise control and operates at high speed. This ensures fast and accurate packaging, increasing overall production output.

Automatic Alarming and Safety Features: Our packing machine includes automatic alarming functions, triggering a stop when inadequate air pressure is detected. This feature prevents potential errors and ensures optimal operational safety.

Adjustable Speed and Precision Bag Feeding: The machine boasts a high-precision horizontal bag feeding device with adjustable speed. This feature allows for tailored packaging processes, accommodating different product requirements.

Reliable and Durable: We prioritize quality by incorporating components from renowned brands. This ensures the reliability and durability of our packing machine, providing long-lasting performance.

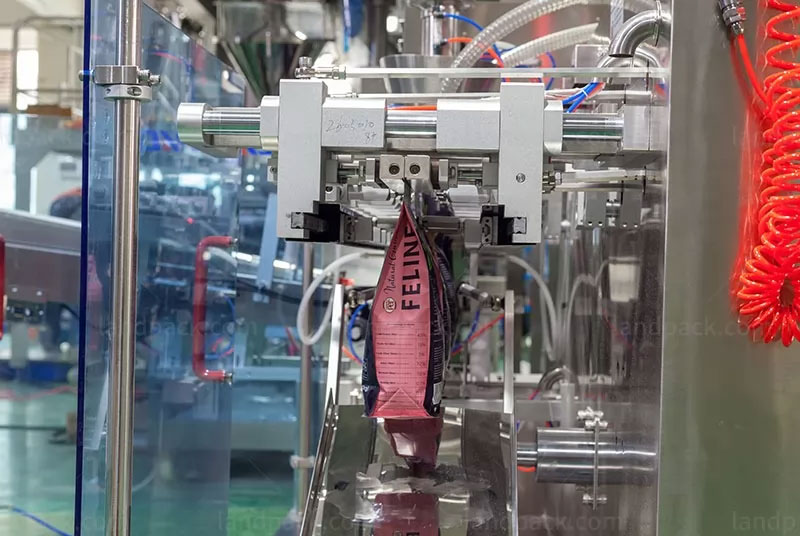

Efficient Zipper Opening: Our machine efficiently and accurately opens zippers on pouches, facilitating easy access to the contents and enhancing user convenience.

Accurate Measurement for Beautiful Packaging: Our packing machine excels in measuring and dispensing heavy-weight powders. This results in beautiful packaging with precise quantities, enhancing the overall product presentation.

Vacuum Cleaning for Clean Bag Mouths: To maintain cleanliness, our machine incorporates a vacuum cleaning system that effectively cleans the bag's mouth. This ensures hygienic packaging and enhances product integrity.

Smooth Performance and Environmentally Friendly: Our packing machine operates smoothly and quietly, delivering a perfect package appearance. Additionally, it features sensible safety devices and produces no pollution during production, creating a friendly working environment.