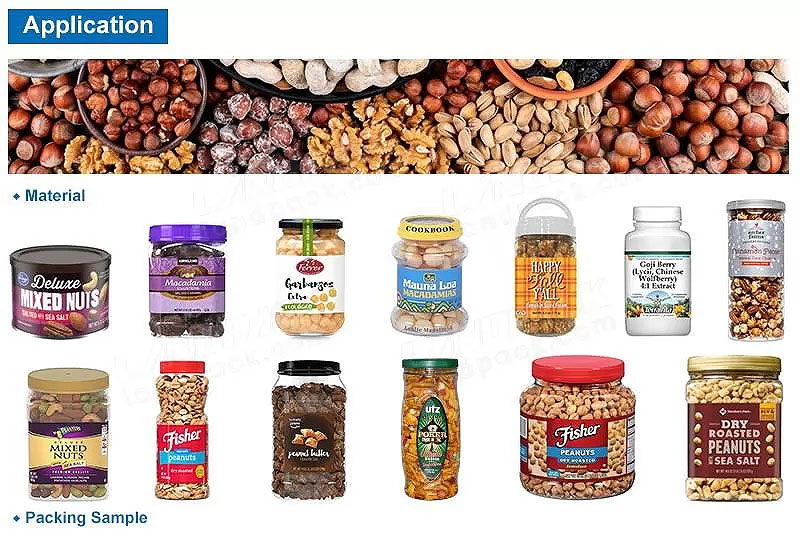

Automatic nuts bottle capping and labeling machine, Ii is used for canned food, sealing, capping, and labeling the cans. Can effectively reduce air contact and extend the shelf life, such as goji berries, nuts, raisins, popcorn, pistachios, and other foods.

Filling Containers:

Bottles; plastic cans; glass cans; tinplate cans; cartons, etc.

Kindly Reminder:

Please tell us the following information when you send us an inquiry. Based on your message, we will suggest the optimum solution to you for reference. Thank you.

1. Your product

2. Bottles/Cans/Tins material

3. Bottles/Cans/Tins dimension

| Packaging Material & Packing Style: |

|

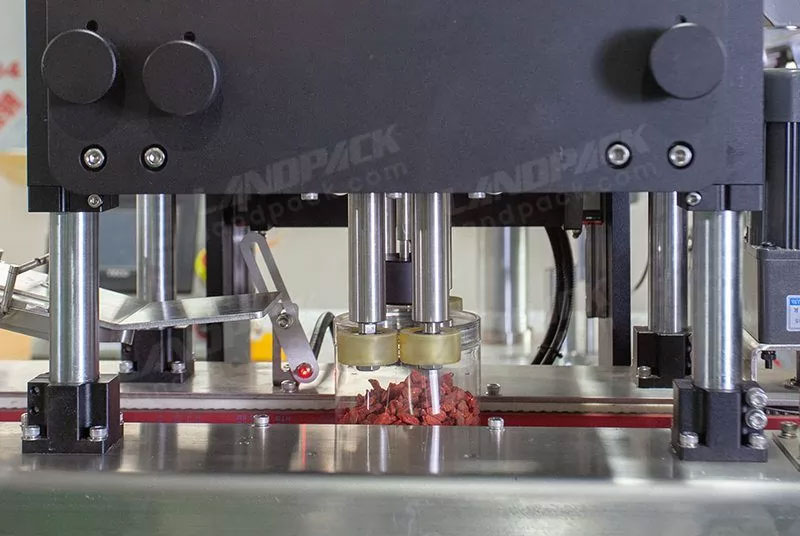

Versatile and Durable Can Seaming Machine Roller: Our production line features a unique design can seaming machine roller that serves both as the main and backup roller. Made of high-hardness chromium steel, it ensures long-lasting performance without rusting.

Efficient and Reliable Automatic Cover Lifting: With a lifting-type automatic cover, our production line offers fast cover speed, stable operation, low noise, and a wide application range. It guarantees efficient and reliable sealing for various products.

Enhanced Capping Performance: Our production line incorporates a four-wheel clamping system, providing a simple and reliable structure that prevents slipping and cap damage. This design significantly improves capping efficiency and ensures consistent results.

Versatility in Cap Compatibility: Designed to accommodate screw caps and anti-theft and child-proof caps, our production line surpasses other machines that handle duckbill caps, pump head caps, and sprinkler caps. It offers superior versatility for different packaging needs.

Quick and Tool-Free Adjustments: The capping mechanism of our production line allows for quick adjustments in spacing and height. Switching between different bottle types and caps is effortless, requiring no tools throughout the process. Simply adjust the hand wheel for seamless replacements.

Precise and High-Speed Labeling: Our production line employs a clip-on positioning round bottle labeling machine that utilizes rollers to rub labels onto products. This innovative approach ensures high precision and speed, enhancing overall labeling accuracy.

Improved Labeling Accuracy and Ease of Use: Unlike traditional belt-type rubbing labels, our labeling machine eliminates labeling errors caused by vertical movement. Its simple and compact structure makes it easy to operate and maintain, guaranteeing consistent and error-free labeling.

User-Friendly PLC Control and Touch Screen Interface: Equipped with an imported PLC and a 7-inch touchscreen interface, our production line offers parameterized control and a user-friendly experience. It simplifies operation and allows for efficient production parameter adjustments.

GMP Certified and Widely Applicable: Our production line meets the requirements of Good Manufacturing Practice (GMP) certification, ensuring stable operation, low noise, and convenient maintenance. It finds extensive applications in the food, cosmetics, and other industries.