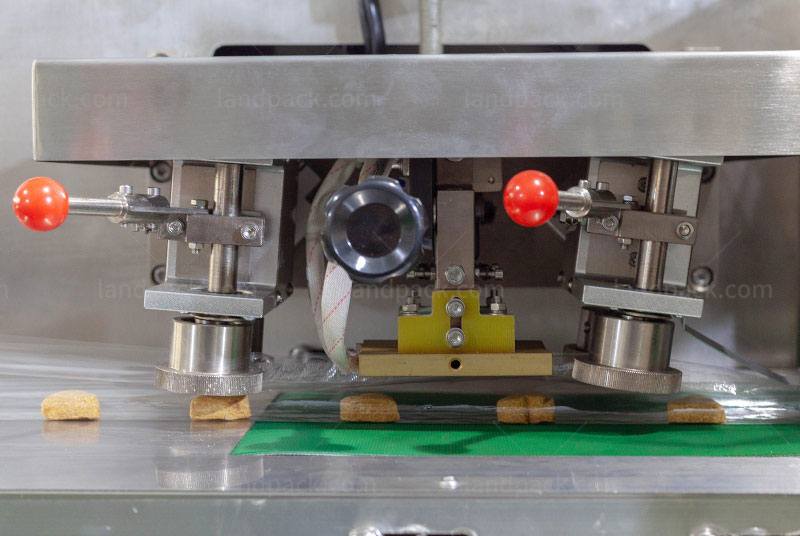

Landpack pet food flow wrap machine is perfect for packaging various items, including dog treats, bread and bakery products, chocolates, sweets, biscuits, vitelline pies, lollipops, moon cakes, ice cream, cards, wet tissues, spoons, toothbrushes, soaps, scourer balls, syringes, hardware, and other non-sticky products with regular shapes.

With its exceptional efficiency and reliability, our packaging machine ensures that your products are securely and attractively packaged. Whether you're in the pet treat industry, confectionery business, or any other sector mentioned above, our machine can streamline your packaging operations and enhance your productivity.

By utilizing our packaging machine, you can save valuable time and resources while maintaining consistent packaging quality. Its adaptable nature allows for easy customization based on your specific product requirements, ensuring seamless integration into your manufacturing process.

|

Packaging Material & Bag Style:

|

|