This machine is mainly used to various material round bottle, flat bottles. Filling material could be small dose of liquid, like IVD reagent diagnostic reagent, pharmaceutical, syrup, essential oil, perfume, Royal jelly, oral liquid, face cream etc.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

|

Bottle And Packaging Style:

|

|

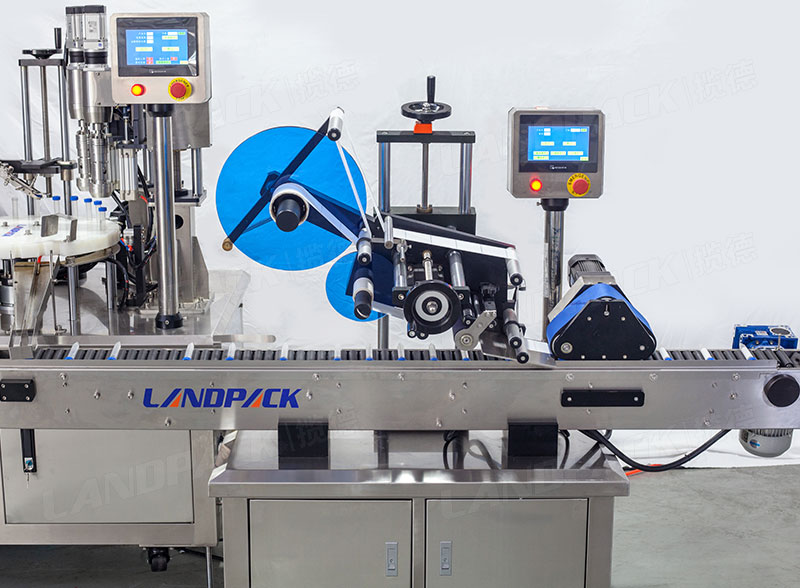

1. It can be equipped with automatic labeling function, visual inspection function, automatic boxing and other functions.

2. PLC, electricity components adopt imported brands Siemens, Panasonic, etc.

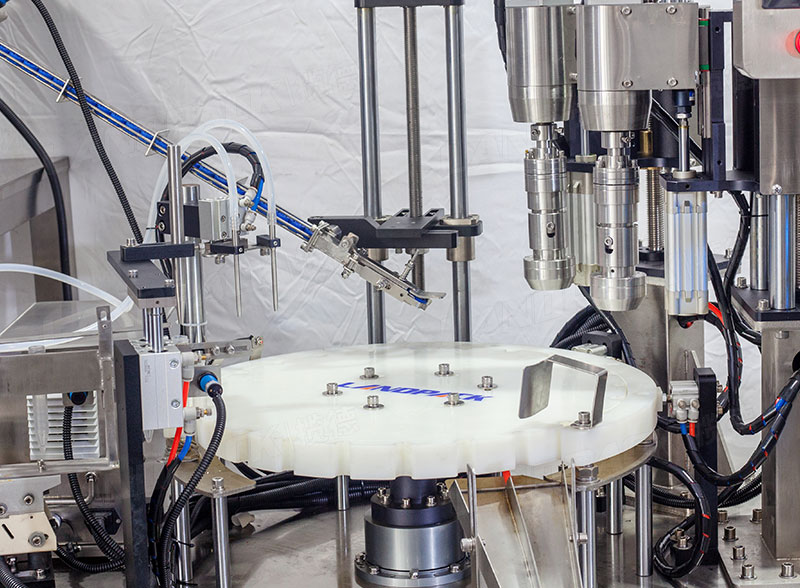

3. Ceramic pump metering device easy to maintain.

4. Using explosion-proof electrical boxes to ensure safer machine operation.

5. Motor control lifting filling to avoid foaming.

6. The fixed rod of the filling nozzle is lengthened, and the width can be flexibly adjusted to suit the filling of different sizes of bottles.

Workflow:

1. Conveyor belt delivers bottles.

2. Cylinder control to stop and release bottles.

3. Submersible filling to eliminate foam generation.

4. Collection table to store bottles.