Application:

This packaging solution is ideal for a wide range of food products, it is compatible with various filling equipment such as screw scales, linear scales, and combined scales.

Examples:

Coffee powder, talcum, milk powder, spice powder, detergent powder, flour and protein powder, etc.

Bag type:

Premade pouch can be 3-side-seal, gussette pouch, standup pouch with zipper or no-zip-lock. Ideal choice for milk powder, glucose, seasoning, washing powder, chemical materials, pesticide, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

|

Packaging Material:

|

|

|

|

|

|

|

|

Coffee Powder

|

Coffee Powder

|

Coffee Powder

|

Coffee Powder

|

Coffee Powder

|

Coffee Powder

|

|

Bag Style:

|

|

Feature:

1.Z-Type Material Handling Elevator: Efficiently elevates materials with a space-saving design.

2.Linear Weigher for Precision Measurement: Delivers accurate weight control, perfect for precise packaging.

3.Space-Efficient Design: Compact structure minimizes the footprint, making it ideal for limited space environments.

4.Specialized for Coffee Products: Linear weigher optimized for ground coffee and coffee beans, ensuring consistent results.

5.Automated Zipper Opening: Streamlines the process by automatically opening pouches with zippers for easy filling.

Basic Functions:

1. The machine stops running when the safety key interlock switch is pulled out;

2. No bag prompting function;

3. Self-diagnosis function of open the bag failed (The bag can be reused); In that case, the machine will not fill and seal, it will re-take the bag;

4. Positioning (anti-dropping) function of hopper;

5. Warning function of cartridge heater fault ;

6. Warning function of cylinder fault.

7. Warning function which air pressure is not up to standard.

Parameter:

|

Model

|

LDB-300A

|

|

Pouch Type

|

Four-side Sealed Bags, stand-up pouches, zipper bags, three-side sealed bags, paper bags, etc.

|

|

Capacity

|

10-20 bags/min

|

|

Bag Size

|

Width:60-120mm Length:55-130mm

|

|

Filling Volume

|

15-200g

|

|

Dimension

|

1800*1200*1500mm(L*W*H)

|

|

Weight

|

1600KG

|

|

Compress air requirement

|

≥0.8m³/min

|

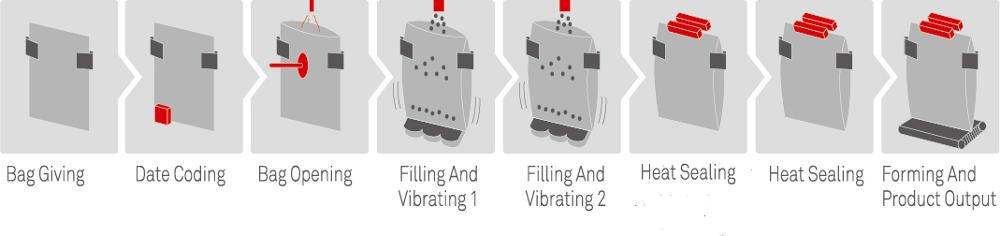

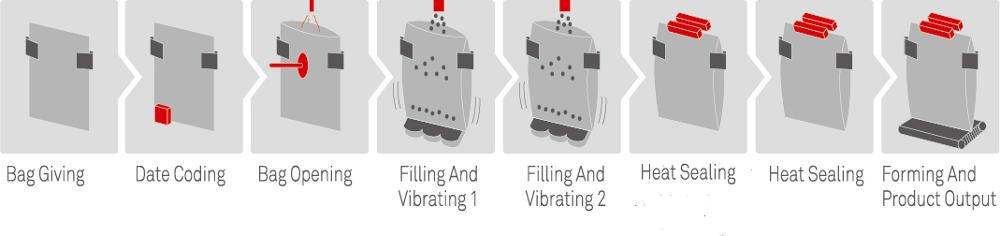

Work Process:

1. Bag giving--Feed many pouches or bags in the bag magazine, our main bag magazine can move up and down, you can feed bags very easily when it moved down, and when it moved up, there are a mechanical arm with two vacuum caps will take the bag up and then transmit it to the mechanical gripper on the rotary table.

2. Date coding--According to the actual production and packaging needs, different types of coding machines are configured to print the date and batch number on the packaging bag.

3. Bag opening--While the suction cup opens the opening of the packaging bag, air is sprayed from the upper nozzle to blow open the bottom of the packaging bag, the packaging bag support plate is inserted into the opening of the packaging bag, and the packaging bag enters the next station.

After inserting the bag support plate into the bag opening, the detection of whether there is a packaging bag and whether the opening of the bag is opened is completed. If there is no packaging bag or there is no opening to open the packaging bag, the next station will not feed.

4. Filling and vibrating 1--According to different packaging materials, different feeders are configured at this station to complete the automatic or semi-automatic delivery of materials.

5. Filling and vibrating 2--According to different packaging materials, different feeders are configured at this station to complete the automatic or semi-automatic delivery of materials.

6. Product settling after filling by vibrating

7. Heat sealing 1--To seal the pouch or bag mouth with a couple of heat sealing air bar, the sealing pattern you can option, net or straight lines.

8. Heat sealing 2--To make the sealing stable and preventing from wrinkling with a couple of cold press, then output the finished production automatically.

9. Forming and product output

Video: