Premade pouch mini doypack packing machine for powder can auto finish material feeding, weighing, premade pouch pick-up, open, fill and seal, etc. Premade pouch can be flat pouch, flat bottom pouch, gusset pouch, stand up pouch without zipper.

Premade pouch mini doypack packing machine for powder, suitable for various kinds of powder products, such as washing powder, coffee powder, matcha powder, curry powder, seasoning powder, flour, protein powder, etc.

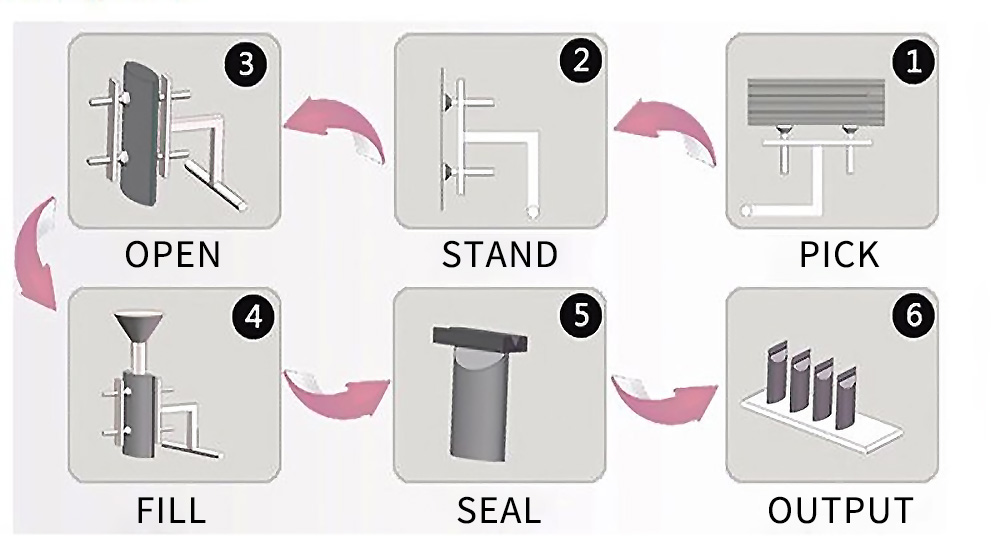

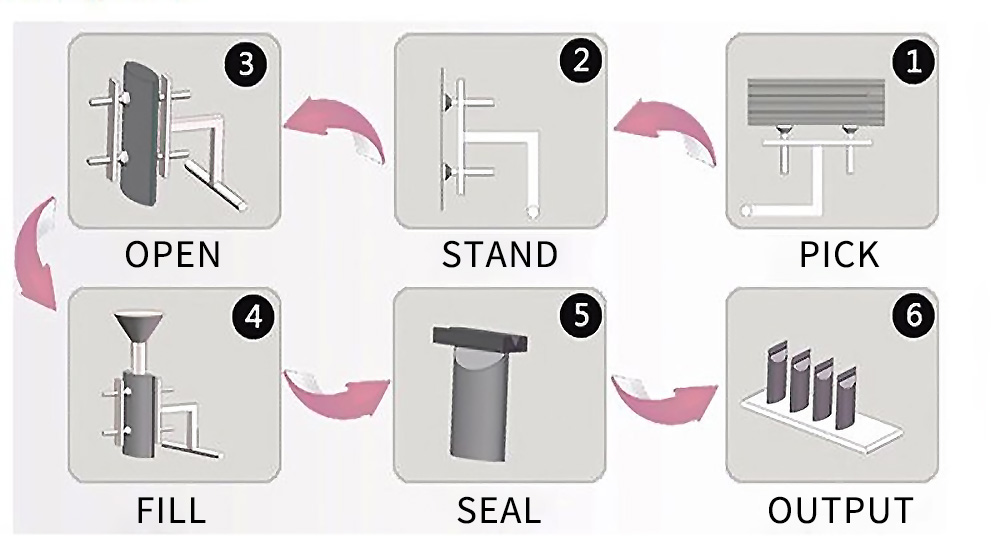

BAG OPENINHG

Pouches are individually removed from the cartridge with a unique combination of vacuum and pneumatic actuators. They are rotated to the fill area and opened.

TRANSITION CHUTE

Doubling as a timing bucket. product enters the transition chute while the bag is being opened below. Upon pouch detection the chute enters the bag and opens its gate. Product is dispensed immediately, without spillage and protecting the seal from contamination. Difficult product that easily bridges is dispensed into the pouch directly from the filler, through the "open-gate''

FILLING

During filling, pouches are held in place with our "posi-hold" gripper system. This allows for heavy weights and shock loads

without disturbing bag Position

SEALING

Digitally controlled ribbed or flat constant heat seal bars give a integral attractive seal. Pouches are sealed ''in place" eliminating wrinkles, folded corners and non aligned seals

MECHINE CONTROLS

System controls are fully solid state. utilizing a commercial Programmable Logic Controller [PLC] and pneumatics. Indicator lights signal all cycle processes for easy monitoring.