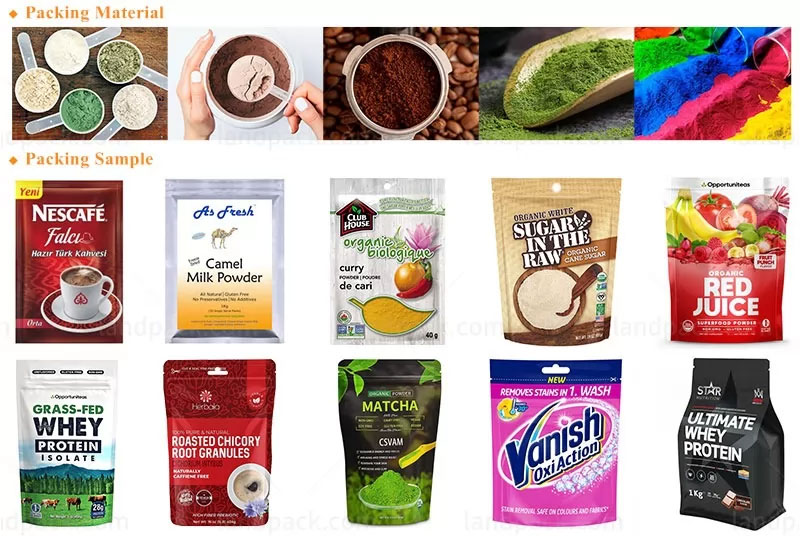

Application:

Whether it's milk powder, coffee powder, flour, seasoning powder, protein powder, talc powder, tea powder, body powder, or any other powdered substance, our cutting-edge three-in-one powder bag packing machine ensures efficient and precise packaging every time.

With its advanced technology and state-of-the-art features, our powder bag packing machine guarantees optimal performance and productivity. The seamless integration of multiple functions streamlines the packaging process, saving valuable time and resources. Say goodbye to manual labor and hello to automated efficiency.

Our machine boasts unparalleled accuracy, ensuring that each bag is filled with the exact amount of powder required. This not only enhances product quality but also reduces wastage and minimizes costs. With precise measurements, you can maintain consistency in your packaging and meet the highest quality standards.

| Bag Style: |

|

Feature:

Versatile Three-in-One Powder Bag Packaging: Our three-in-one powder bag packaging machine offers a comprehensive solution, combining metering, filling, and sealing processes for various powder products.

Efficient Automation with Auger Powder Filler: Experience seamless automation with our fully automatic intermittent rotary preformed bags dispensing, opening, and closing machine, equipped with an automatic auger powder filler for precise and consistent filling.

Enhanced Safety and Durability: Our packaging machine is built to last, featuring high-speed and consistent production capabilities with safety guard protection. We have carefully selected heavy-duty components and parts to ensure durability and longevity.

Hygienic Stainless Steel Construction: Designed to meet food hygiene standards, our three-in-one powder bag packing machine is crafted from stainless steel. This material not only simplifies the cleaning and disinfection process but also guarantees a hygienic packaging environment.

User-Friendly Interface with Advanced PLC: With an advanced programmable logic controller (PLC) and a user-friendly touchscreen interface, our packaging machine provides a seamless man-machine interaction, making operation and control effortless.

Optional Dust Control and Extractor System: Upon request, we offer a dust control and extractor system to maintain a clean and controlled packaging environment, ensuring product integrity.

Reliable Bag Checking and Sealing: Our automatic checking system meticulously examines bag positioning, as well as the filling and sealing process, ensuring accurate and reliable packaging results.

Parameter:

| Model |

LD-8200D/ 8240D/ 8300D |

| Packing material |

3-side, four edge-sealing bag, self-reliance bag, handbag, spout bags, zipper bag, compound bag, etc |

| Size |

L: 100-450mm, W: 100-300mm |

| Filling range |

5-2500g |

| Packing speed |

25-60 bags/min |

| Average precision |

≤ ±1% |

| Total power |

2.5KW |

| Dimensions |

1900mm*1570mm*1700mm (L*W*H) |

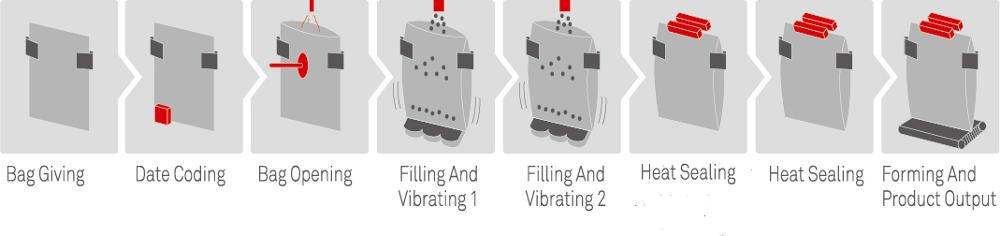

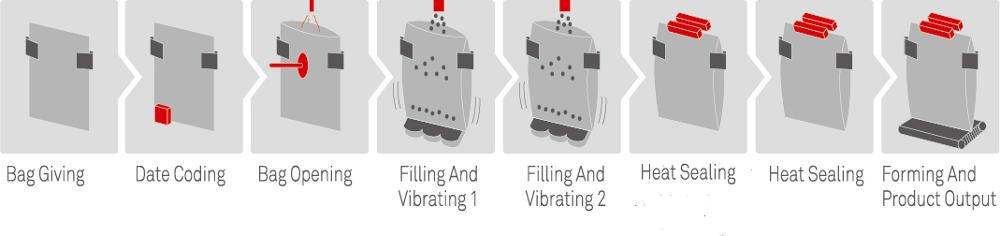

| Workflow |

Giving bag→coding→opening→filling 1→filling 2→auxiliary→exhaust→heat sealing→forming and output product |

Work Process:

1. Bag giving--Feed many pouches or bags in the bag magazine, our main bag magazine can move up and down, you can feed bags very easily when it moved down, and when it moved up, there are a mechanical arm with two vacuum caps will take the bag up and then transmit it to the mechanical gripper on the rotary table.

2. Date coding--According to the actual production and packaging needs, different types of coding machines are configured to print the date and batch number on the packaging bag.

3. Bag opening--While the suction cup opens the opening of the packaging bag, air is sprayed from the upper nozzle to blow open the bottom of the packaging bag, the packaging bag support plate is inserted into the opening of the packaging bag, and the packaging bag enters the next station.

After inserting the bag support plate into the bag opening, the detection of whether there is a packaging bag and whether the opening of the bag is opened is completed. If there is no packaging bag or there is no opening to open the packaging bag, the next station will not feed.

4. Filling and vibrating 1--According to different packaging materials, different feeders are configured at this station to complete the automatic or semi-automatic delivery of materials.

5. Filling and vibrating 2--According to different packaging materials, different feeders are configured at this station to complete the automatic or semi-automatic delivery of materials.

6. Product settling after filling by vibrating

7. Heat sealing 1--To seal the pouch or bag mouth with a couple of heat sealing air bar, the sealing pattern you can option, net or straight lines.

8. Heat sealing 2--To make the sealing stable and preventing from wrinkling with a couple of cold press, then output the finished production automatically.

9. Forming and product output

Video: