The filling machine is mainly suitable for packing all kinds of flammable and explosive liquids, such as alcohol, drinks, chemical liquids, hand sanitizer, alcohol liquor, lubricating oil, petrol, etc.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

|

Bottle And Packaging Style:

|

|

1. 6 nozzles filling device.

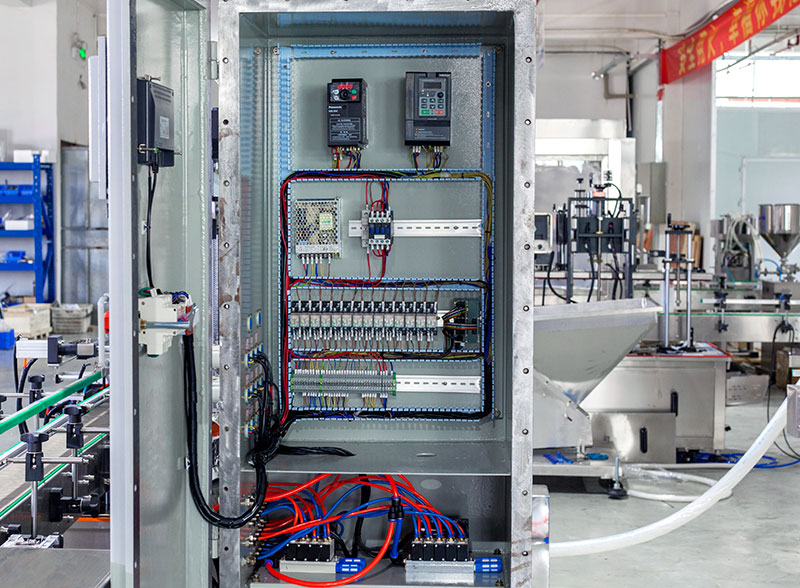

2. PLC, electricity components adopt imported brands Siemens, Panasonic, etc.

3. Gear pump metering device easy to maintain.

4. Using explosion-proof electrical boxes to ensure safer machine operation.

5. Motor control lifting filling to avoid foaming.

6. The fixed rod of the filling nozzle is lengthened, and the width can be flexibly adjusted to suit the filling of different sizes of bottles.

Workflow:

1. Conveyor belt delivers bottles.

2. Cylinder control to stop and release bottles.

3. Submersible filling to eliminate foam generation.

4. Collection table to store bottles.