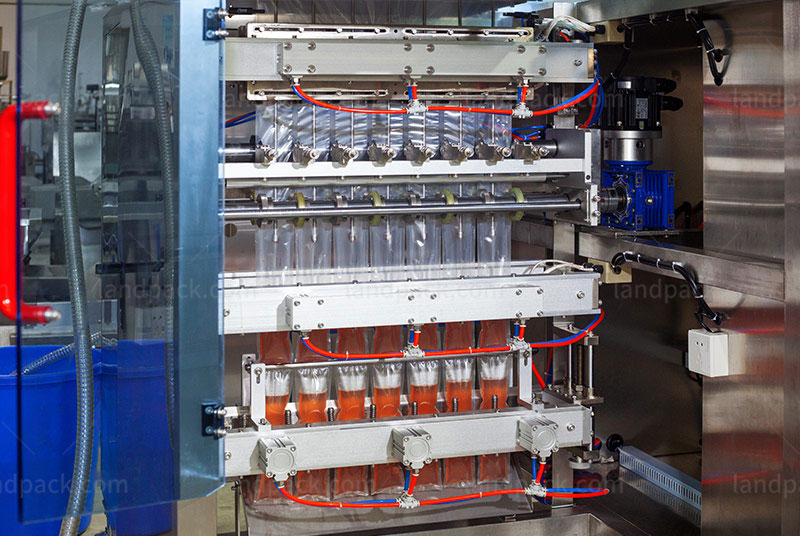

This cutting-edge packaging solution is perfect for various applications including ketchup, sauce, honey, oil, jelly, shampoo, facial cream, and more. With its advanced technology and versatility, our machine ensures efficient and precise packing of these liquid products.

Our multilane packing machine boasts exceptional adaptability, allowing it to handle different viscosities and consistencies with ease. Whether you're packaging thick and sticky substances like ketchup or thin and runny liquids like oil, our machine guarantees consistent and reliable results.

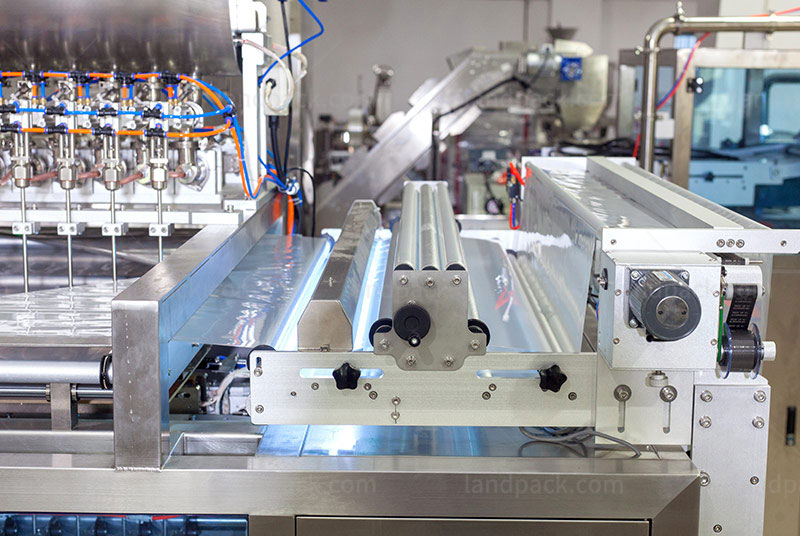

Not only does our packing machine offer superior functionality, but it also enhances productivity. Its multilane design enables the simultaneous packing of multiple sachets, significantly increasing output capacity and reducing production time. This feature makes it an ideal choice for manufacturers who require high-volume production without compromising on quality.

Furthermore, our ketchup sachet packing machine prioritizes hygiene and product safety. It incorporates industry-leading sanitary standards, ensuring that the packed liquid products maintain their quality and integrity. The machine's construction materials and design facilitate easy cleaning and maintenance, minimizing the risk of contamination and promoting a sterile packaging environment.

| Packaging Material: |

|

|

|

|

|

|

| Milk |

Juice |

Honey |

Oil |

Salad dressing |

Sauce |

| Bag Style: |

|