In recent years, vacuum bag packaging machines have gradually occupied a dominant position in the packaging market. The many advantages of vacuum bags, such as excellent transparent appearance, portable opening method (easy to tear), and user-friendly sealing method, keep food fresh, making it the first choice of consumers. Vacuum bags provide seafood and frozen food manufacturers with more packaging options, material handling strategies and fully automated solutions.

High Speed Rotary Vacuum Doy Bag Packaging Machine is suitable for packaging vegetable, fruit, frozen food, soybean products, meat products, egg products, kelp, pickle, seafood and other food that require vacuum packaging.

| Packaging Material: |

|

|

|

|

|

|

| Pickle |

Pickle |

Kelp |

Kelp |

Pickle |

Pickle |

| Bag Style: |

|

|

|

|

|

|

| Vacuum pouch |

Vacuum pouch |

Vacuum pouch |

Vacuum pouch |

Vacuum pouch |

Vacuum pouch |

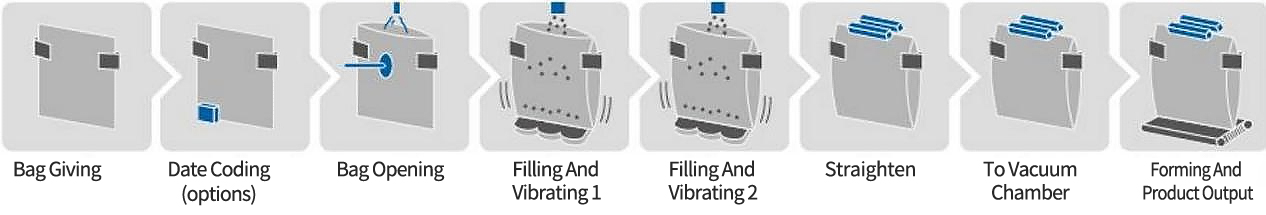

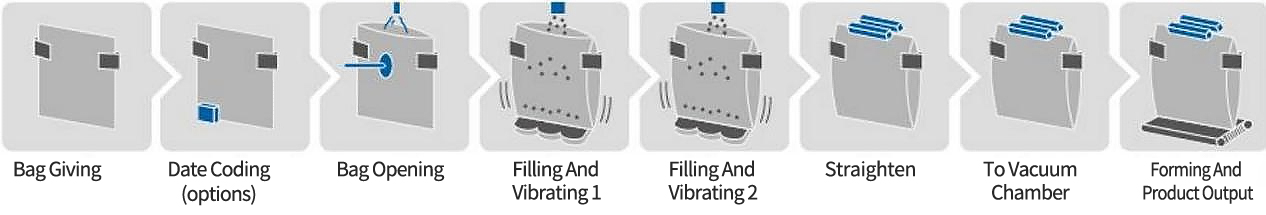

1. Bag giving--Feed many pouches or bags in the bag magazine, our main bag magazine can move up and down, you can feed bags very easily when it moved down, and when it move up, there is a mechanical arm with two vacuum caps will take the bag up and then transmit it to the mechanical gripper on the rotary table.

2. Date coding(options)--According to the actual production and packaging needs, different types of coding machines are configured to print the date and batch number on the packaging bag.

3. Bag opening--While the suction cup opens the opening of the packaging bag, the air is sprayed from the upper nozzle to blow open the bottom of the packaging bag, the packaging bag support plate is inserted into the opening of the packaging bag, and the packaging bag enters the next station.

After inserting the bag support plate into the bag opening, the detection of whether there is a packaging bag and whether the opening of the bag is opened is completed. If there is no packaging bag or there is no opening to open the packaging bag, the next station will not feed.

4. Filling and vibrating 1--According to different packaging materials, different feeders are configured at this station to complete the automatic or semi-automatic delivery of materials.

5. Filling and vibrating 2--According to different packaging materials, different feeders are configured at this station to complete the automatic or semi-automatic delivery of materials.

6. Straighten--Straighten the bag and check whether there are materials in the bag at the same time. If there is no material in the packaging bag, it will not be transferred into the vacuum chamber.

7. To vacuum chamber--The transfer manipulator between the two turntables transfers the packaging bags from the bag feeding turntable to the vacuum turntable. The packaging bag with the mouth of the packaging bag not opened or without materials added will not be passed into the vacuum chamber, and the packaging bag can be recycled and used again after it is dropped at this station.

8. Forming and product output