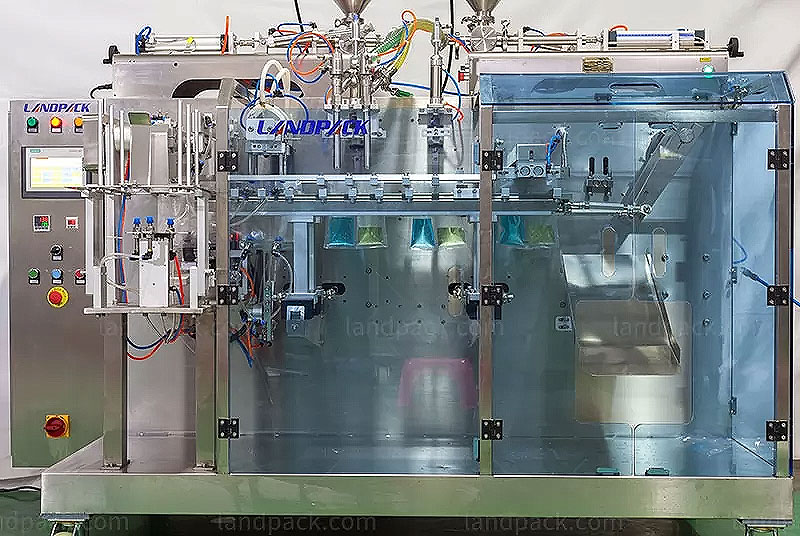

In recent years, horizontal liquid twin pouch packaging machine in the packaging market gradually occupies a dominant position. Many advantages of the liquid premade pouch, such as excellent appearance, portable opening, and user-friendly sealing method, make it the first choice of consumers. Premade pouch provides manufacturers with more packaging options, material handling strategies, and fully automated solutions.

Automatic Liquid Twin Pouch Horizontal Doypack Machine can auto finish material feeding, weighing, premade pouch pick-up, open, fill and seal, etc. Premade pouch can be twin pouch, shaped pouch, liquid pouch, spout pouch, stand up pouch with spout, cocktail package, stand up pouch, etc.

Automatic Liquid Twin Pouch Horizontal Doypack Machine is suitable for fruit juice, milk, honey, oil, sauce, salad dressing, laundry detergent, sauce, rice vinegar, beverage, tomato sauce, peanut butter, jam, paste, etc.

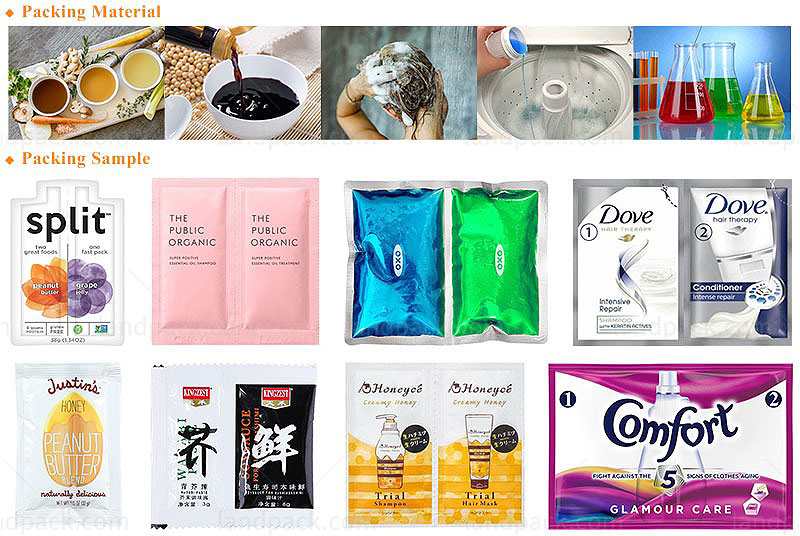

| Packaging Material: |

|

|

|

|

|

|

| Milk |

Juice |

Honey |

Oil |

Salad dressing |

Sauce |

| Bag Style: |

|

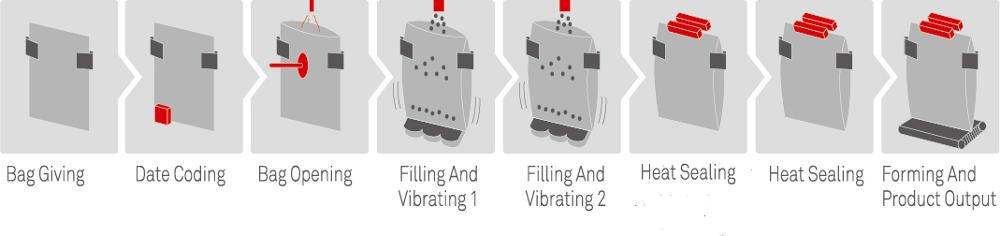

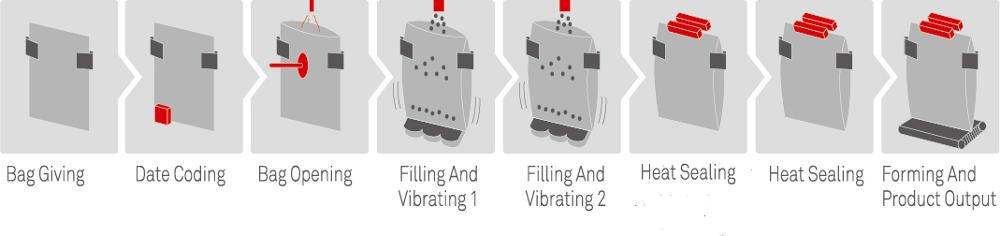

Bag giving > Date coding> Bag opening > Filling and vibrating 1 > Filling and vibrating 2 > Product settling after filling by vibrating> Heat sealing> Forming and product output