Application:

Landpack mixed nuts mini zipper pouch stand up pouch filling sealing machine with 4 vibration plate is perfect for efficiently packing a wide range of products, including nuts, spices, biscuits, beans, oats, candy, coffee beans, chocolate, pet food, potato chips, popcorn, dried fruits, and more.

Designed to accommodate conventional granular zipper bags, standing bags, and pre-made bags, our filling and sealing machine ensures a seamless packaging process. With its advanced features, you can experience increased productivity and precision in your packaging operations.

The 4 vibration plates integrated into the machine enhance the filling process by effectively settling the contents within the pouches. This results in improved bag stability and consistency, ensuring that your products are securely packaged every time.

| Packaging Material: |

|

|

|

|

|

|

| Nuts |

Nuts |

Nuts |

Nuts |

Nuts |

Nuts |

| Bag Style: |

|

Feature:

Affordable Vibration Plate Weighing Machine: Discover an economical solution for weighing with our vibration plate weighing machine, designed to offer accurate measurements at a budget-friendly price point.

Premium Nut Mix with Four Varieties: Indulge in a delightful assortment of nuts with our carefully crafted mix that combines four different types, ensuring a flavorful and satisfying snacking experience.

Intelligent Ink Jet Printer with Touchscreen Interface: Enhance your printing process with our cutting-edge inkjet printer featuring a user-friendly touchscreen interface. Set and customize information effortlessly, making your printing tasks more intelligent and efficient.

Efficient Product Selection with Metal Detector: Streamline your quality control processes with our advanced metal detector. With high efficiency, it accurately selects only the qualified products, ensuring optimal product integrity and safety.

Parameter:

| Model |

GP-160C |

| Bag Material |

Multilayer Composite Premade Bag (e.g.: PET/PE) |

| Bag Size |

70mm≤W≤150mm, 70mm≤L≤150mm |

| Speed |

0-60 bags/min |

| Sealing Type |

Straight grain, the pitch is 1mm (Optional reticulate) |

| Sealing Width |

10 mm (5-20 mm can be customized) |

| Voltage |

220 V, Single-phase, 50/60 HZ, 1.2 KW |

| Air Pressure |

0.65 Mpa |

| Air Consumption |

0.3 m³/min (Standard machine, no additional function) |

| Body Dimension |

1770*600*1260 mm |

| Packing Dimension |

1860*710*1650 mm (Export non-fumigation wooden case) |

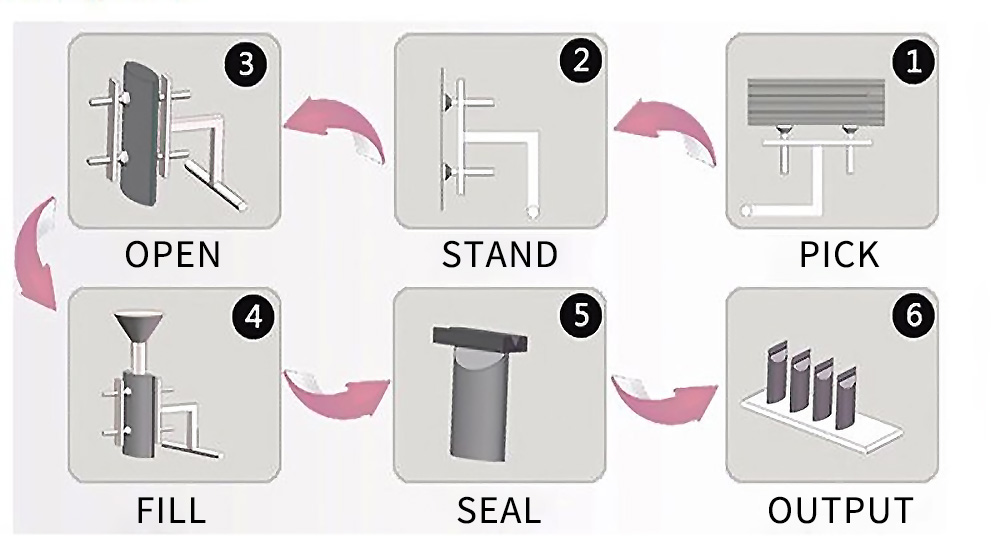

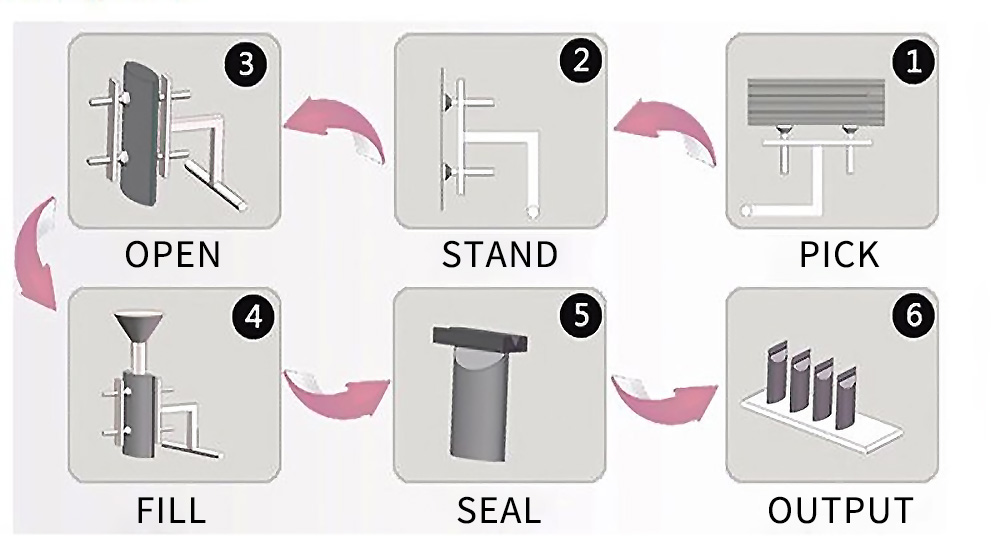

Work Process:

Pouches are individually removed from the cartridge with a unique combination of vacuum and pneumatic actuators. They are rotated to the fill area and opened

Doubling as a timing bucket. product enters the transition chute while the bag is being opened below. Upon pouch detection, the chute enters the bag and opens its gate. Product is dispensed immediately, without spillage and protecting the seal from contamination. The difficult product that easily bridges is dispensed into the pouch directly from the filler, through the "open-gate''

During filling, pouches are held in place with our "posi-hold" gripper system. This allows for heavyweights and shock loads without disturbing the bag Position

Digitally controlled ribbed or flat constant heat seal bars give a integral attractive seal. Pouches are sealed ''in place" eliminating wrinkles, folded corners and nonaligned seals

System controls are fully solid state. utilizing a commercial Programmable Logic Controller [PLC] and pneumatics. Indicator lights signal all cycle processes for easy monitoring

Video: