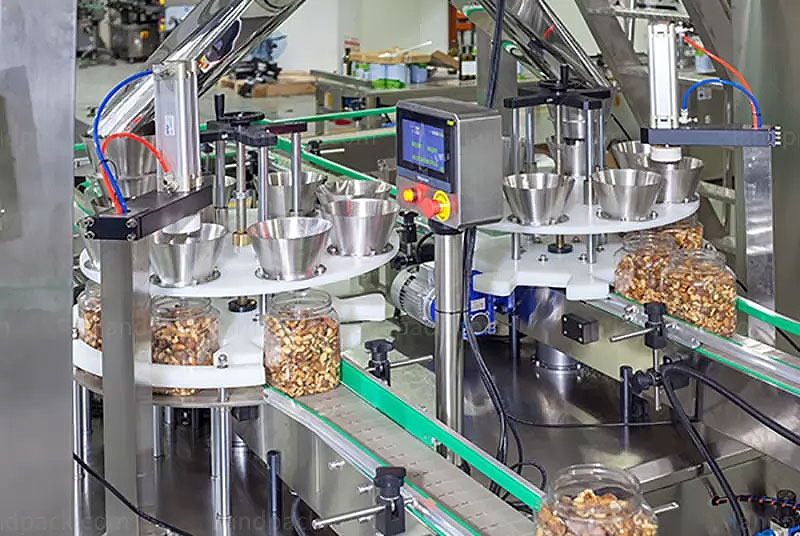

Automatic granule bottle weighing filling and capping line is suitable for dry fruit, beef jerky, nuts, beans, peanuts, snacks, cashew, sugar, rice, beans, condiments, washing powder, feed, desiccant, plastic pellets, grains, etc.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

|

Packaging Material & Bottles Style:

|

|

1. The whole line of round bottles and square bottles are shared, with strong compatibility.

2. The conveying line enters the bottle to save labor.

3. Multi-head combined scale metering turntable filling, high combination precision, and turntable lifting speed.

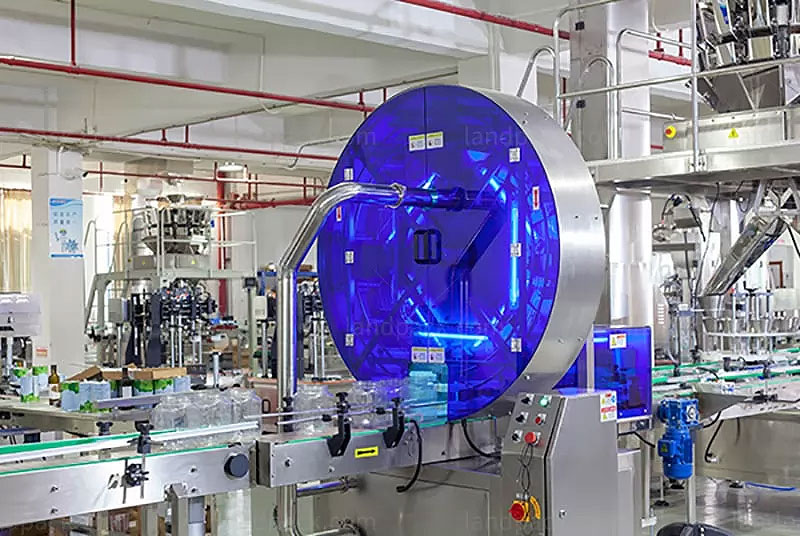

4. Equipped with a UV sterilizer, which can sterilize the inside of the bottle and recover dust before filling, so as to achieve the cleaning effect in the tank.

5. Equipped with nitrogen filling and aluminum foil sealing, product insurance, and extended shelf life.

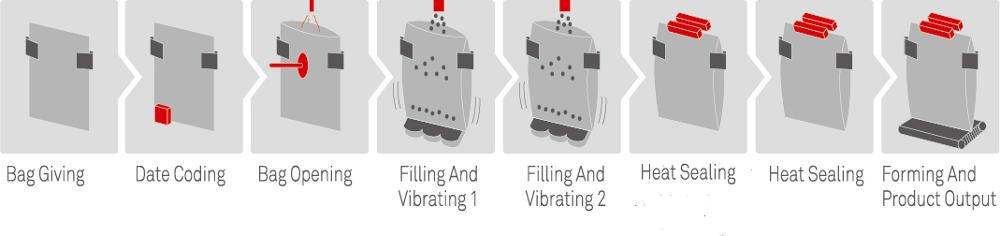

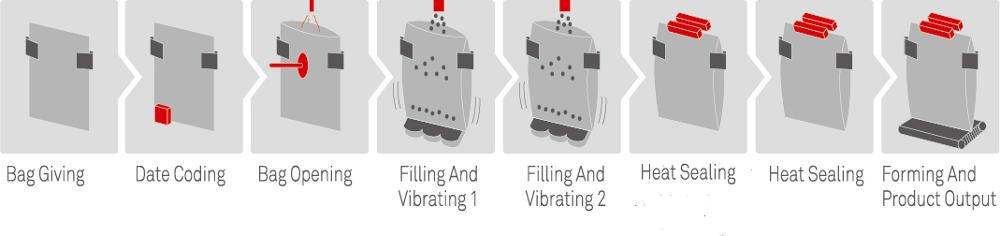

1. Bag giving--Feed many pouches or bags in the bag magazine, our main bag magazine can move up and down, you can feed bags very easily when it moved down, and when it moved up, there is a mechanical arm with two vacuum caps will take the bag up and then transmit it to the mechanical gripper on the rotary table.

2. Date coding--According to the actual production and packaging needs, different types of coding machines are configured to print the date and batch number on the packaging bag.

3. Bag opening--While the suction cup opens the opening of the packaging bag, the air is sprayed from the upper nozzle to blow open the bottom of the packaging bag, the packaging bag support plate is inserted into the opening of the packaging bag, and the packaging bag enters the next station.

After inserting the bag support plate into the bag opening, the detection of whether there is a packaging bag and whether the opening of the bag is opened is completed. If there is no packaging bag or there is no opening to open the packaging bag, the next station will not feed.

4. Filling and vibrating 1--According to different packaging materials, different feeders are configured at this station to complete the automatic or semi-automatic delivery of materials.

5. Filling and vibrating 2--According to different packaging materials, different feeders are configured at this station to complete the automatic or semi-automatic delivery of materials.

6. Product settling after filling by vibrating

7. Heat sealing 1--To seal the pouch or bag mouth with a couple of heat sealing air bars, the sealing pattern you can option, net or straight lines.

8. Heat sealing 2--To make the sealing stable and preventing from wrinkling with a couple of cold presses, then output the finished production automatically.

9. Forming and product output