Automatic granule snack bottles filling capping packaging line suitable for packing banana chips, plantain chips, coated peanuts, medicine, potato chips, and other powder and granular materials into bottles and cans packing, can also pack cashew nuts, peanuts, almonds, etc.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

| Packaging Material & Bottles Style: |

|

1. Equipped with safety protection, and comply with the firm's safety management requirements.

2. Flexible applications for Grain, Granule, or Granules mixing liquids materials Bottling or Canning by changing different dosing equipment. Granule and Grain products dosing by Multi-heads Weigher or Liner Weigher. Liquid products dosing by Piston filler or Pump.

3. Use PLC Servo System and pneumatic control system and super touch screen to compose the drive control center which maximizes the whole machine's control precision, reliability and intelligentized level.

4. Touch screen can store the technical parameters of various kinds of products, it is unnecessary to reset while products changing.

5. With an error indicating system, which helps to handle the trouble immediately.

6. Available to connect with the Capping machine, check weigher, Labelling machine, and cartooning machine to get the whole bottles or Cans packaging filling line.

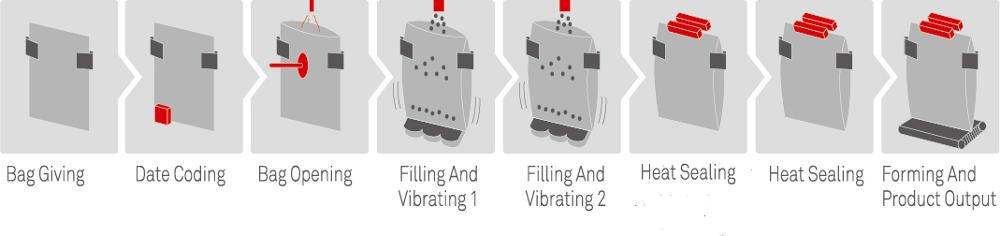

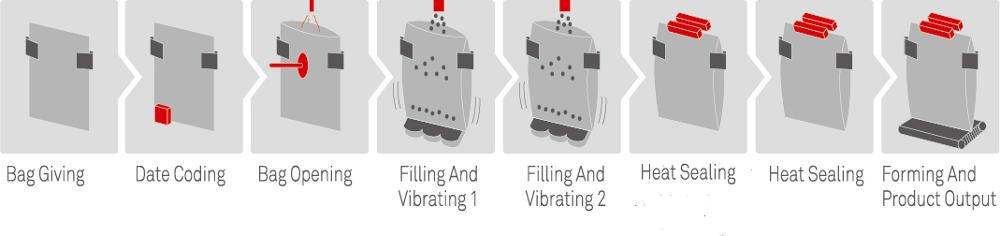

1. Bag giving--Feed many pouches or bags in the bag magazine, our main bag magazine can move up and down, you can feed bags very easily when it moved down, and when it moved up, there is a mechanical arm with two vacuum caps will take the bag up and then transmit it to the mechanical gripper on the rotary table.

2. Date coding--According to the actual production and packaging needs, different types of coding machines are configured to print the date and batch number on the packaging bag.

3. Bag opening--While the suction cup opens the opening of the packaging bag, the air is sprayed from the upper nozzle to blow open the bottom of the packaging bag, the packaging bag support plate is inserted into the opening of the packaging bag, and the packaging bag enters the next station.

After inserting the bag support plate into the bag opening, the detection of whether there is a packaging bag and whether the opening of the bag is opened is completed. If there is no packaging bag or there is no opening to open the packaging bag, the next station will not feed.

4. Filling and vibrating 1--According to different packaging materials, different feeders are configured at this station to complete the automatic or semi-automatic delivery of materials.

5. Filling and vibrating 2--According to different packaging materials, different feeders are configured at this station to complete the automatic or semi-automatic delivery of materials.

6. Product settling after filling by vibrating

7. Heat sealing 1--To seal the pouch or bag mouth with a couple of heat sealing air bars, the sealing pattern you can option, net or straight lines.

8. Heat sealing 2--To make the sealing stable and preventing from wrinkling with a couple of cold presses, then output the finished production automatically.

9. Forming and product output