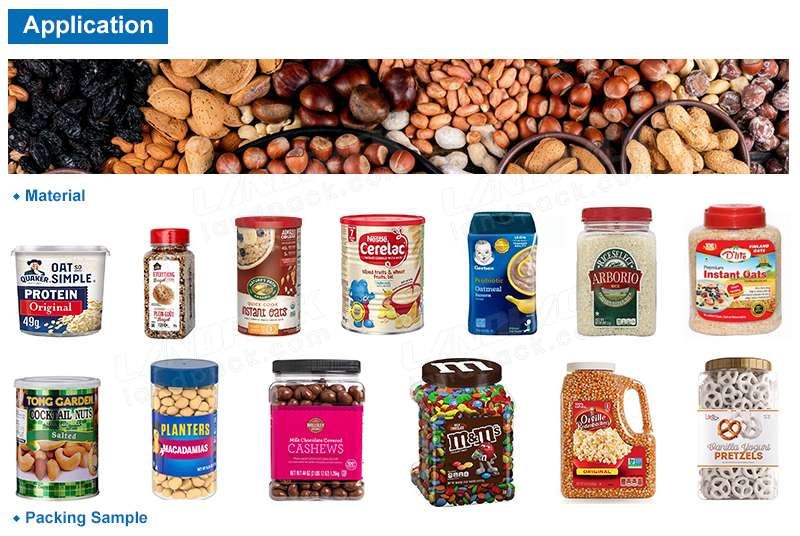

Automatic granule nut weighing filling machine, It is suitable for filling granular products such as nuts, popcorn, potato chips, puffed food, peanuts, beans, capsules, tablets, etc.

Filling Containers:

Bottles; plastic cans; glass cans; tinplate cans; cartons, etc.

Kindly Reminder:

Please tell us the following information when you send us an inquiry. Based on your message, we will suggest the optimum solution to you for reference. Thank you.

1. Your product

2. Filling Range

3. Bottles/Cans/Tins material

4. Bottles/Cans/Tins dimension

| Packaging Material & Packing Style: |

|

High Efficiency and Intelligent Automation: Our production line incorporates advanced automation technology, including imported PLC, inspection light eye, frequency converter, and pneumatic components. This ensures high efficiency, intelligent operation, and wide adaptability, resulting in improved productivity and stability.

Fully Automated Production Line: With automatic bottle feeding, linear filling machine, can sealing machine, and bottle collecting machine, our production line offers a seamless and fully automated process. This streamlines operations reduces manual labor, and enhances overall efficiency.

Durable and Aesthetically Pleasing Design: The machine frame of our production line is constructed using SUS304 material, known for its durability and corrosion resistance. Additionally, the sleek design adds an aesthetic appeal to the equipment, making it visually appealing and long-lasting.

Compliance with GMP Certification: Our production line adheres to Good Manufacturing Practices (GMP) standards, ensuring that it meets the highest quality and safety requirements. It is widely used in various industries, including medicine and food, where strict compliance with regulations is essential.

User-Friendly Operation: Equipped with an imported PLC and a 7-inch touchscreen man-machine interface, our production line offers easy and intuitive operation. Users can navigate through the system effortlessly, making adjustments and monitoring the process with convenience.

Customizable Solutions: We understand that different customers have unique requirements. Therefore, we offer flexible customization options to tailor our production line according to specific needs. This ensures that our customers receive a solution that perfectly matches their production demands.