Designed to cater to a wide range of powder products, this innovative packing machine is perfect for various applications such as health powder, protein powder, collagen powder, medicine powder, flour, milk powder, coffee powder, glucose, medical powder, nutrition powder, and more.

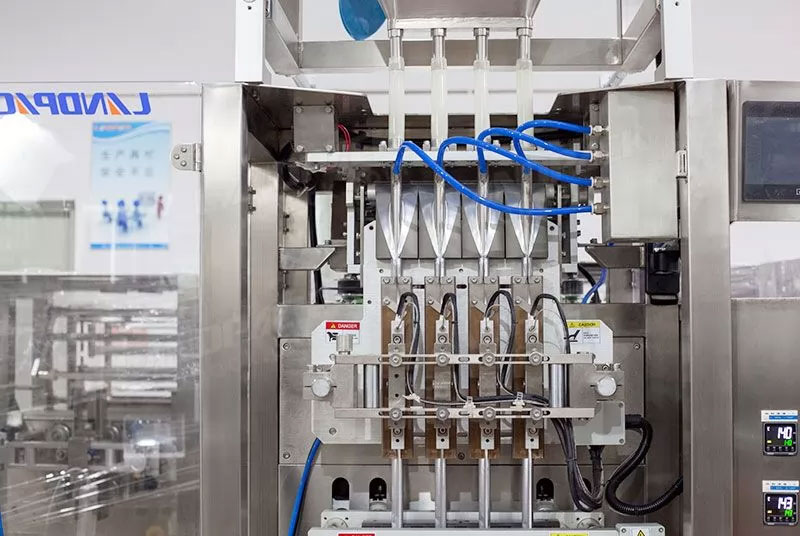

With its advanced technology and multi-track functionality, our packing machine offers exceptional flexibility and efficiency. It ensures precise and accurate packaging, providing your customers with reliable and consistent product quality. Whether you're in the health and wellness industry or the pharmaceutical sector, our machine delivers outstanding performance to meet your specific requirements.

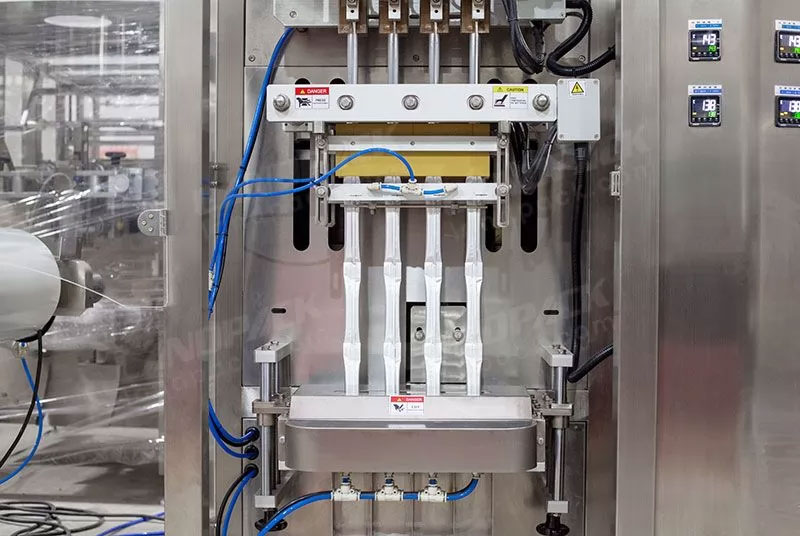

Crafted with precision engineering, our Multi-Track Protein Powder Stick Packing Machine boasts user-friendly operation and minimal maintenance needs. Its intelligent control system allows for easy parameter adjustments, ensuring seamless production and reducing downtime. Additionally, its high-speed capabilities enable swift packaging of your powder products, optimizing productivity and maximizing your output.

| Packaging Material: |

|

|

|

|

|

|

| Protein Powder |

Protein Powder |

Protein Powder |

Protein Powder |

Protein Powder |

Protein Powder |

| Bag Style: |

|